High Temperature Disperse Dyes for Direct Printing on Textiles.

In comparison to heat transfer sublimation on fabric, the dispersed dye coloration system offers excellent stability, tones with high definition and rich saturated colors.

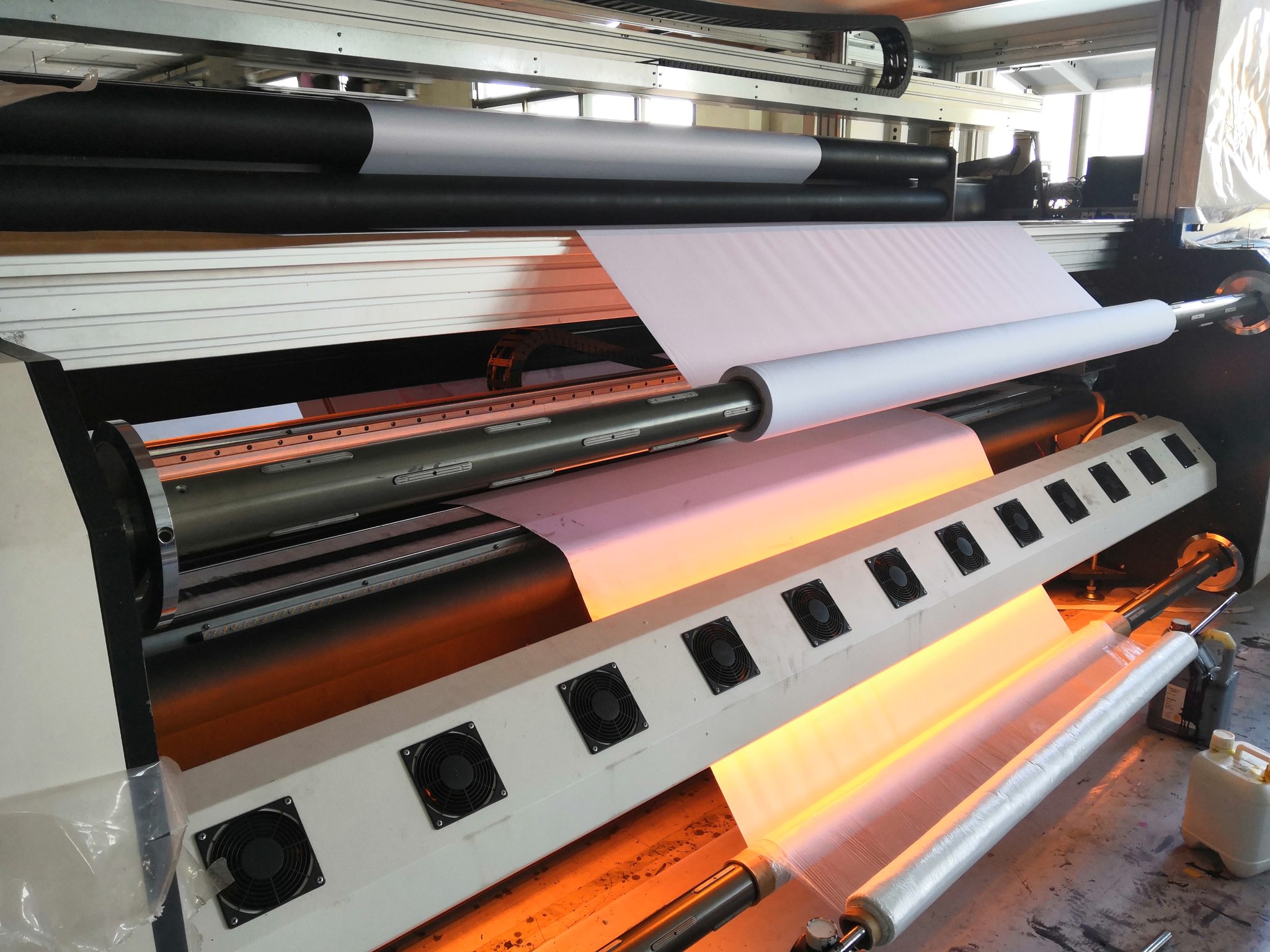

High energy disperse dye ink is preferred for direct textile printing on many textiles over the transfer printing processes which uses low energy pigment inks. High energy,or high temperature processing passes the fabric over heated rollers before

accepting the dye, each fabric with its own tolerances determines the volume of ink that can be accepted into the fibers.

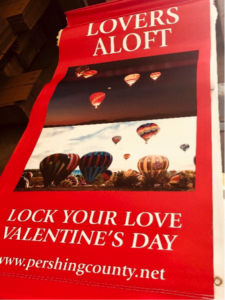

By eliminating transfer paper, direct textile printing has much deeper penetration, binding deep into the fibers vs transferring set amounts of ink through a carrier, then reheating to sublimate the fabric. This has been particularly helpful in achieving saturated, colorfast images and improving longevity on heavier textiles that are used for outdoor banners, tent canopies and similar. The process is also environmentally friendly by eliminating the waste associated